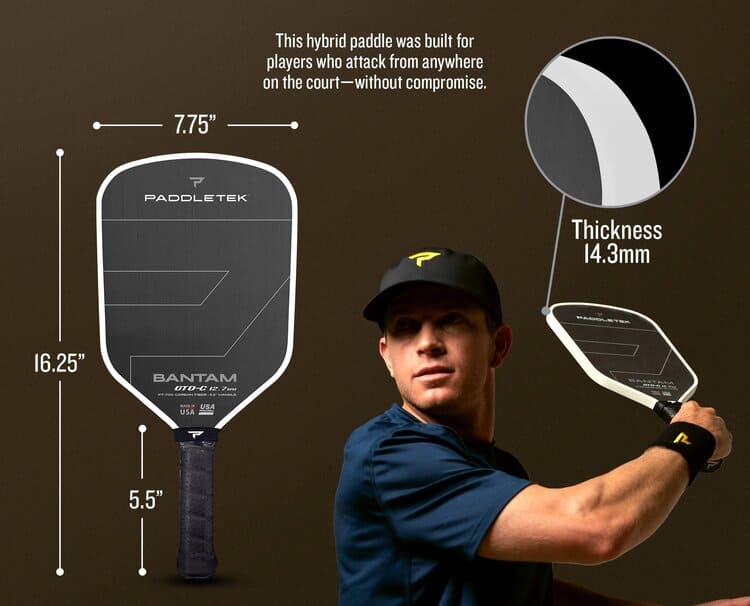

Paddletek Bantam GTO — This Is Not Just a Paddle, It’s a Weapon

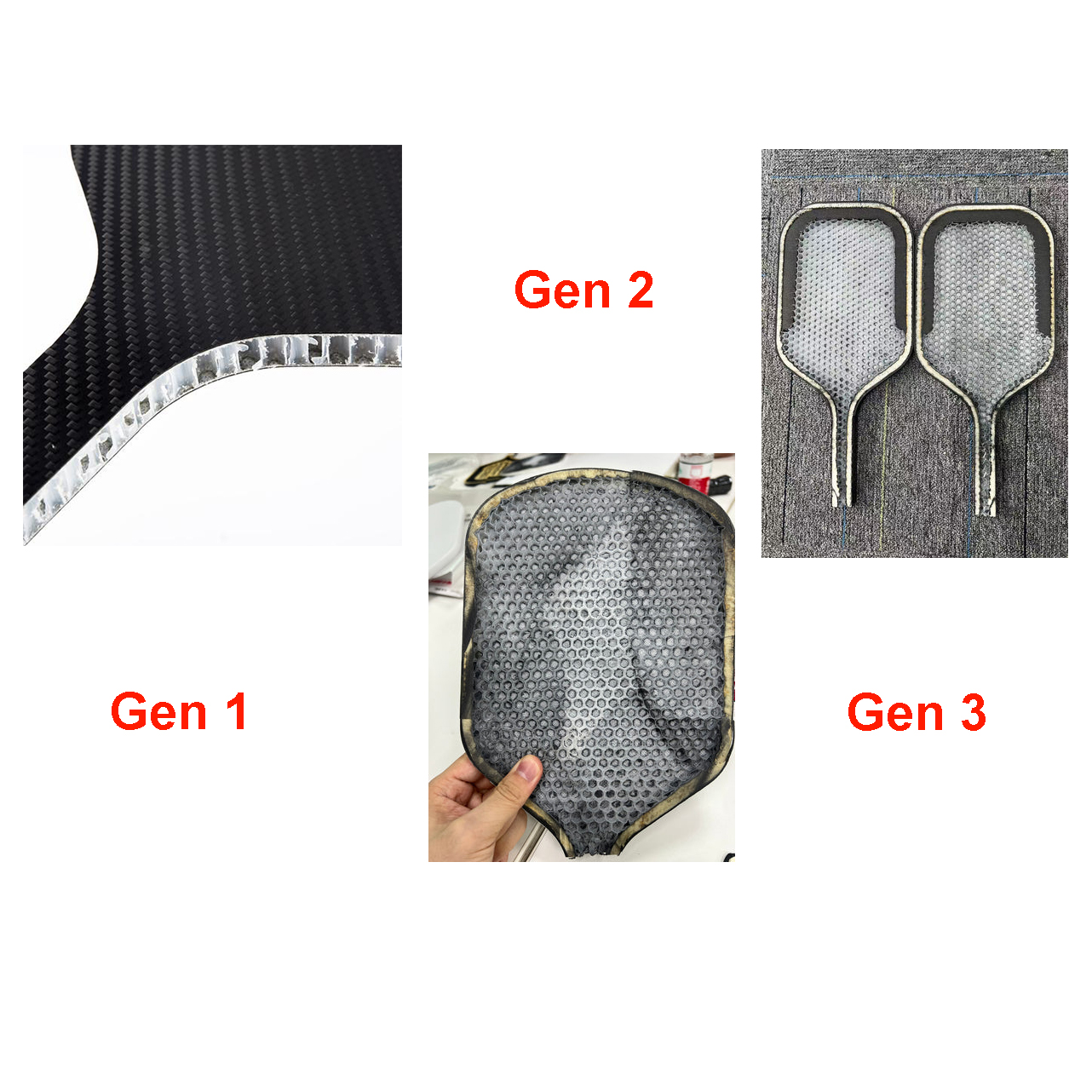

The Paddletek Bantam GTO isn’t just a paddle — it’s a precision weapon for aggressive players. Featuring aerospace-grade PT700 carbon fiber, cold-pressed construction, and a meticulously engineered hybrid shape, the GTO offers explosive power, fast hands, and brutally honest feedback. This is not a control paddle — it’s a performance machine designed to amplify your strengths and expose your weaknesses. Should you get it? This in-depth review breaks it down.