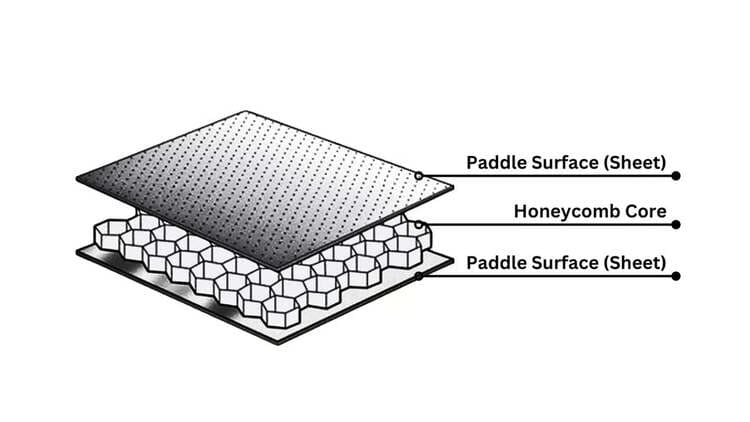

In the world of pickleball, we’re often obsessed with how a paddle feels in hand — the pop of a drive, the finesse of a drop, the explosive energy of a serve. But have you ever considered that the most important layer of your paddle might not be the flashy carbon face you see, but rather what lies underneath — the core layer?

The core plays a pivotal role in determining the paddle’s performance, and modern paddles typically rely on polymer honeycombs, EVA foams, or hybrid constructions. As players and engineers continue searching for the ideal balance between feel, control, and power, one material may offer a breakthrough: PEBA.

What Is PEBA?

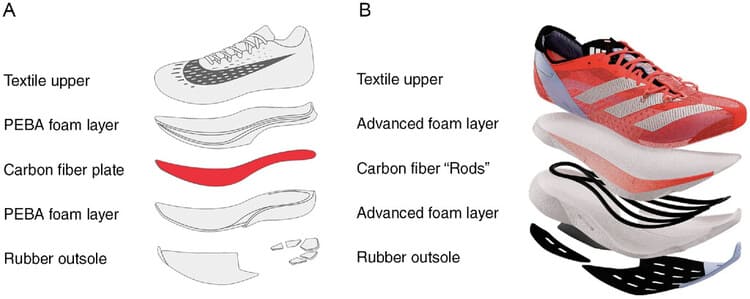

PEBA stands for Polyether Block Amide, a thermoplastic elastomer originally developed by Arkema in 1981 under the commercial name Pebax®. If you’re into running, you might recognize it — Nike uses PEBA in the midsoles of its elite marathon shoes due to its exceptional energy return and lightness.

Put simply, PEBA is lightweight, springy, durable, and comfortable — a material engineered for performance. It handles extreme temperatures, resists fatigue, and retains its properties under stress — qualities that make it a serious contender for next-generation pickleball paddle cores.

What Happens When You Use PEBA as the Core?

To understand its potential, let’s look at PEBA’s key material characteristics:

| Property | PEBA Traits | Implications for Pickleball Paddles |

|---|---|---|

| Elasticity | High energy return, rubber-like flexibility | Boosts ball speed and enhances touch |

| Low Density | ~1.01 g/cm³ | Reduces paddle weight, improves maneuverability |

| Shock Absorption | Excellent fatigue resistance | Damps vibrations, increases comfort |

| Processability | Suitable for molding, extrusion, lamination | Compatible with modern paddle manufacturing |

| Weather Resistance | Performs in cold, heat, humidity | Great for outdoor durability |

How Does PEBA Compare to Traditional Core Materials?

| Core Material | Pros | Cons |

|---|---|---|

| Polypropylene (PP) Honeycomb | Light, low cost, decent stiffness | Mediocre rebound, feels firm |

| Nomex® Honeycomb | High stiffness and thermal resistance | Heavier, less forgiving feel |

| PEBA (Solid or Foamed) | Superior rebound, softer touch, light weight | Requires structural reinforcement and bonding solutions |

Feasible PEBA Core Integration Concepts

1. PEBA Foam Core (Closed-Cell)

Similar to EVA foam but lighter and more responsive.

Advantages: High energy return, shock-absorbing, soft feel.

Challenges: Must fine-tune foam density to prevent “bottoming out” and loss of control.

2. PEBA + Fiberglass Composite Laminate

PEBA sheets or films laminated with carbon or fiberglass under heat/pressure.

Advantages: Creates a unique “springy” feel; tunable stiffness.

Challenges: Needs surface treatment or special adhesives to ensure strong bonding with fiber layers.

3. PEBA Honeycomb Structure (Advanced Concept)

3D printed or injection-molded honeycomb made of PEBA.

Advantages: Could combine structure and elasticity in a single component.

Challenges: Costly to scale; thermal stability and moldability require R&D.

Technical & Production Challenges

| Challenge | Description | Recommended Solutions |

|---|---|---|

| Adhesion | PEBA's surface is smooth and chemically inert | Plasma/chemical surface treatment, primer adhesives |

| Stiffness Support | PEBA is softer than PP or Nomex | Use multilayer constructions or rigid face materials |

| Thermal Sensitivity | Can soften above 180°C | Choose high-temp grades (e.g., Pebax 5533); lower lamination temps |

| Cost | PEBA is more expensive than standard polymers | Use in premium paddles or in partial-core designs |

Could PEBA Replace Traditional Core Materials?

In the short term, not entirely. Polypropylene and EVA still dominate due to their low cost and well-established supply chains. However, for brands seeking elite-level performance, PEBA could become the go-to for high-end paddles, especially as advanced lamination and hybrid-core tech mature.

Final Thoughts

PEBA isn’t a magic fix-all — but it’s a highly promising “next-gen core candidate”. As carbon fiber faces, edge-free designs, and variable-density cores evolve, the paddle’s heart — its core — deserves equal attention.

PEBA brings something that few materials do: a rare balance between bounce, feel, and durability. It may not dethrone PP tomorrow, but it could very well be the foundation of the next big leap in pickleball paddle design.

The End about Mayvoci

1)Design:Over 100 paddle designs and photography service to assist start-up.

2)Professional:Focus on various of paddles manufacturing for 6 years

3)Quality:Strict quality management system to provide safety and satisfaction for customers

4)Amazon:Flexible comprehensive solution to make sure each Amazon seller is well cared.

5)Excellent Team:Experienced paddle experts & dynamic sales team give you 5-star service