In a highly competitive market, securing lower wholesale prices is crucial for enhancing profit margins and market competitiveness. This article explores various effective strategies, including leveraging economies of scale through bulk purchasing, utilizing negotiation skills to secure better pricing, conducting in-depth cost analysis and ensuring price transparency, establishing long-term partnerships and strategic alliances, as well as prompt payment and market trend utilization. By employing these methods, companies can ensure a stable and sustainable supply chain at the most competitive prices without compromising quality.

Minimum Order Quantity (MOQ) is a critical element in supply chain management that not only determines supplier profitability but also influences buyer procurement strategies. This article delves into the definition of MOQ, the reasons behind its establishment, and the multiple benefits it offers to buyers. By examining key factors that affect MOQ, such as materials, production processes, and profit margins, this piece provides valuable insights into how MOQ is applied in real-world business scenarios. Additionally, it addresses common concerns, including strategies for handling unmet MOQs and the potential risks of working with suppliers offering unusually low MOQs. This article is designed to help businesses make better procurement decisions, optimize supply chain management, and enhance their competitive edge in the market.

Minimum Order Quantity (MOQ) is a critical element in supply chain management that not only determines supplier profitability but also influences buyer procurement strategies. This article delves into the definition of MOQ, the reasons behind its establishment, and the multiple benefits it offers to buyers. By examining key factors that affect MOQ, such as materials, production processes, and profit margins, this piece provides valuable insights into how MOQ is applied in real-world business scenarios. Additionally, it addresses common concerns, including strategies for handling unmet MOQs and the potential risks of working with suppliers offering unusually low MOQs. This article is designed to help businesses make better procurement decisions, optimize supply chain management, and enhance their competitive edge in the market.

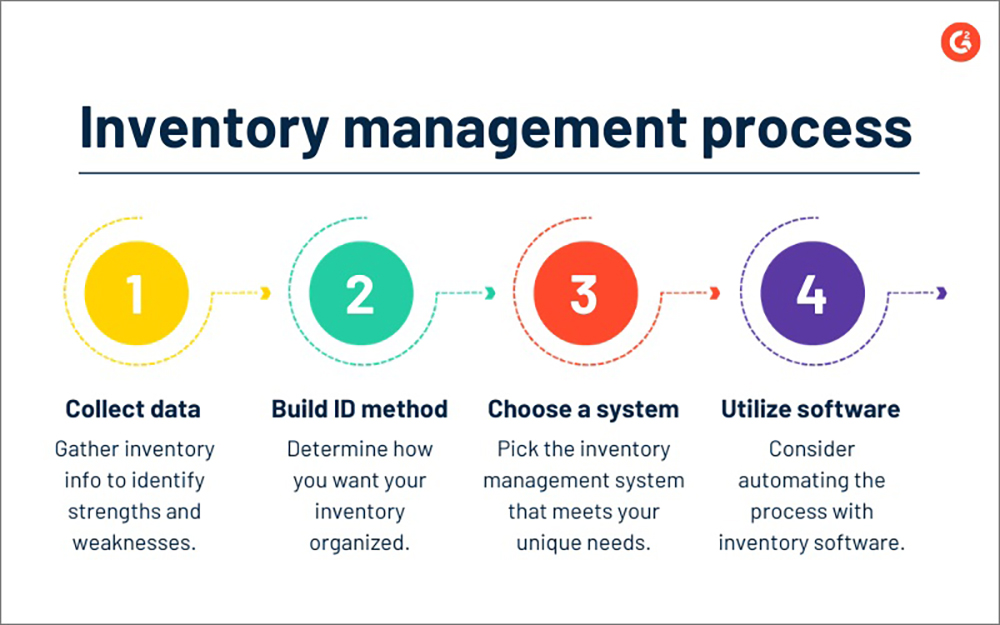

Effective inventory management is crucial for the operational efficiency and cost control of any business, particularly for those manufacturing and selling Pickleball Paddles. This article provides a stepbystep guide to optimizing inventory management, including selecting appropriate inventory management software, setting safety stock levels, implementing the ABC classification method, conducting regular inventory counts, and setting reasonable reorder points.

Turning retailers into your salespeople is an effective strategy to boost product sales. This article explains how to achieve this by establishing partnerships, offering incentives, providing training and support, and maintaining continuous communication. These methods can motivate retailers to actively promote your products, increasing sales and market share.

Understanding the importance and influencing factors of Manufacturer's Suggested Retail Price (MSRP) is crucial when setting it. This article provides a detailed explanation of MSRP, its influencing factors, pricing strategies, and its role in the market, helping businesses to set a reasonable MSRP to ensure market competitiveness and maximize profits.

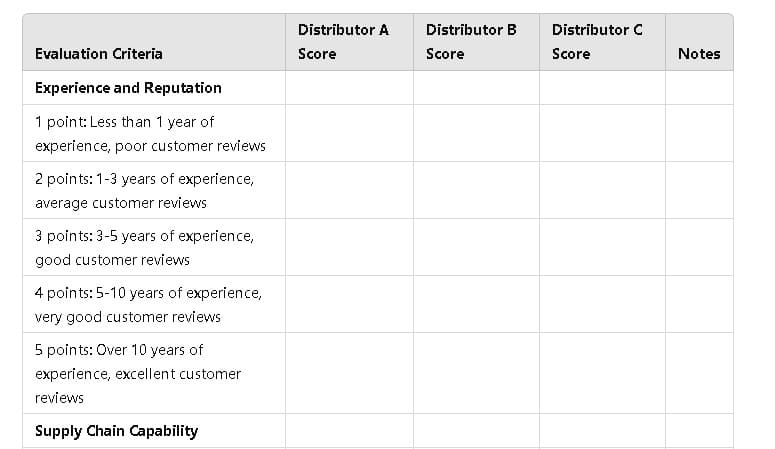

Choosing the right distributor is crucial for success in the pickleball market. This article outlines how to find and manage suitable pickleball paddle distributors by clarifying needs, conducting market research, evaluating qualifications, establishing cooperative relationships, and continuous optimization. It provides detailed evaluation criteria and a specific scoring table to help companies systematically evaluate and select high-quality distributors, gaining a competitive edge in the market.

Supply Chains

Xiaxitou No.471, Tongan District, Xiamen, Fujian 361100 – China

Quick links

- About us

- FAQs

- Product catalog

- How to cutdown cost

- Material introduction

- Production process

- Customized service

Find Us

Join us to develope pickleball and Win-Win together!