“Thermoformed” is the buzzword every high-end pickleball paddle brand uses today. But when you pick up different paddles all boasting the same manufacturing process, you encounter a puzzling reality: their performance, feel, and feedback are worlds apart.

As manufacturers deeply embedded in this industry, we’re pulling back the curtain. The term “thermoforming” describes not a single step, but a complex system of material science, thermodynamics, and precision engineering. The subtle, often undisclosed variations in this process are what truly define the paddle in your hand.

Let’s move beyond the marketing and into the factory, examining how unseen parameters—from temperature curves to mold precision—silently engineer your playing experience.

01 Temperature Control: The Soul of the Process

Temperature is the most critical parameter, but it’s far more complex than just “heating to X degrees.” It involves a meticulously crafted time-temperature profile where each stage dictates the final outcome.

The Ramp-Up Phase: Setting the Foundation

- Controlled Ramp Rates: A rapid temperature increase (>10°C/min) causes volatile compounds to erupt, creating micro-bubbles and internal stress. A slow, controlled climb (2-5°C/min) allows the resin to flow evenly, fully saturating every fiber.

- Stepped Heating: Advanced systems use multi-stage heating. For example, a soak at 80°C brings the resin to an optimal viscosity, a step to 100°C drives off volatiles, and a final climb to the cure temperature. This precision is what separates advanced manufacturing from basic heating.

The Cure Cycle: Where Performance is Forged

Different resin systems have specific cure windows. Epoxy resins typically cure best between 125-135°C, while some high-performance variants require 150°C or more. A deviation of just ±3°C can result in under-cured (weak) or over-cured (brittle) resin, directly impacting the paddle’s stiffness, toughness, and durability.

The Cooldown: Managing Internal Stress

The cooling phase requires equal precision. Rapid cooling causes uneven shrinkage, locking in residual stresses that can lead to long-term warping or performance decay. A programmed, slow cooldown (1-2°C/min) is essential for stress relief and ensuring product stability over time.

| Temperature Parameter | Result of Poor Control | Ideal Control Strategy |

|---|---|---|

| Ramp-Up Rate | Internal bubbles, uneven resin distribution | 2-5°C/min with stepped holds |

| Cure Temperature | Weak or brittle resin structure | ±1°C accuracy within material-specific window |

| Soak Time | Incomplete cure or material degradation | Precisely calculated based on resin Tg |

| Cooldown Rate | Internal stress, risk of deformation | 1-2°C/min programmed cooldown |

02 Pressure Application: An Art of Force and Timing

Pressure ensures the carbon fiber layers bond into a single, unified structure. Its application is a delicate balance of science and feel.

Pressure Value: A Calculated Balance

The optimal pressure is calculated based on the material stack and target thickness. Insufficient pressure (<5 kg/cm²) fails to remove air bubbles, creating a hollow, unsatisfying feel on impact. Excessive pressure (>15 kg/cm²) can collapse the polymer core’s honeycomb structure or squeeze out too much resin, creating weak “resin-starved” areas.

The Pressure Window: A Critical Moment

Applying pressure at the right moment is where experience pays off. Pressure must be applied when the resin reaches its “gel point”—viscous enough not to be squeezed out entirely, but fluid enough to allow layers to consolidate. Missing this brief window by mere minutes compromises the entire structure.

Pressure Profiling: Dynamic Adjustment

Sophisticated processes use multi-stage pressure: initial low pressure to remove air, followed by a ramp to ensure resin flow, and a final high pressure at the gel point for consolidation. This dynamic pressure profiling is a hallmark of top-tier manufacturing.

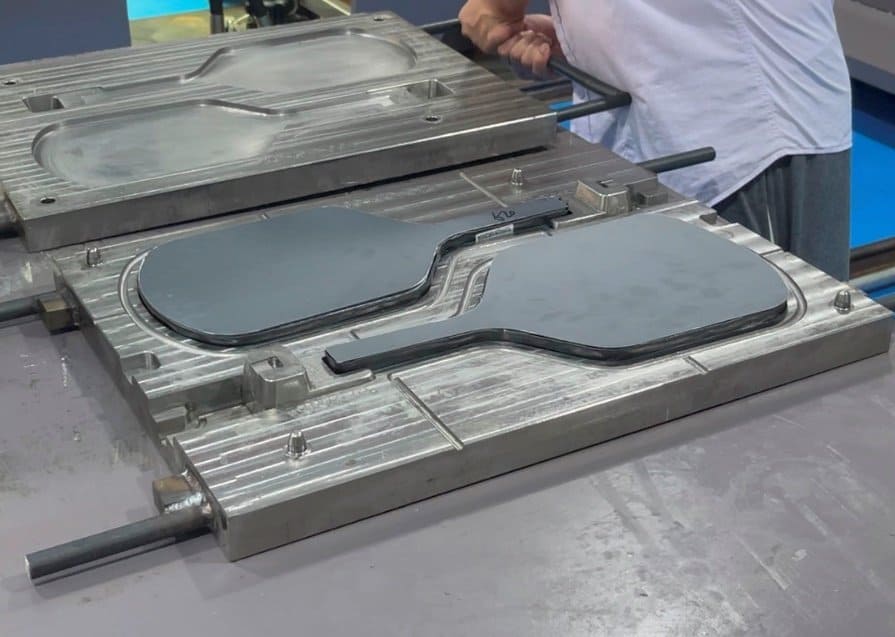

03 Mold Engineering: Precision Dictates Consistency

The mold is the foundation of the thermoforming process. Its quality and precision dictate the paddle’s final form and consistency.

Thermal Expansion Matching: A Foundational Calculation

The mold material and carbon fiber composite have different coefficients of thermal expansion (CTE). Standard mold steel has a CTE of ~11.5×10⁻⁶/°C, while carbon fiber is typically 0.5-5×10⁻⁶/°C. If unaccounted for, this mismatch causes stress and warpage during heating and cooling. Premium molds are engineered to compensate for this differential.

Cavity Precision: A Micron-Level Game

Paddle performance is extremely sensitive to thickness distribution. The sweet spot requires precise thickness for power, while the edges need tapered thinning for maneuverability. A quality mold must maintain cavity accuracy within ±0.02mm; even minor deviations create noticeable differences in play.

Runner & Venting Systems: The Devil in the Details

Precisely calculated runner systems ensure resin fills the cavity evenly. Microscopic venting channels (0.1-0.2mm diameter) allow air and volatiles to escape, preventing voids and dry spots. These micro-features are designed using fluid dynamics simulation and deep practical experience.

| Mold Parameter | Required Precision | Impact on Final Product |

|---|---|---|

| Cavity Flatness | <0.01mm/m | Determines uniform face thickness |

| Surface Finish | Ra <0.2μm | Defines the paddle's surface quality |

| Thermal Balance | ±1.5°C | Ensures even temperature across the paddle |

| Venting System | 0.1-0.2mm diameter | Prevents air traps and voids |

04 The Final Challenge: Demolding and Post-Processing

Demolding is the final, high-risk stage of the process, where a perfect part can be easily ruined.

Release Agent Technology: Ensuring a Flawless Surface

A release agent must form a uniform, ultra-thin (1-3μm) layer. Silicone-based agents are cost-effective but can interfere with later graphics; fluorinated agents perform better but are more expensive. Imperfect application leads to surface marks or difficult demolding.

The Art of Demolding: A Skill of Timing and Touch

Demolding must occur after the paddle has cooled sufficiently (typically below 40°C) to gain structural strength. However, over-cooling increases adhesion due to CTE mismatch, making demolding difficult and risking damage to both the paddle and the mold. A skilled operator uses sound and feel to identify the perfect moment.

Post-Curing: The Hidden Step for Superior Performance

High-end paddles undergo a post-cure cycle after demolding—several hours at a specific temperature to complete the resin cure and relieve internal stresses. This often-overlooked step can improve the paddle’s long-term performance stability by 10-15%.

The gap in thermoforming quality is ultimately a gap in material understanding, equipment control, and accumulated craft. When you choose a paddle, you’re not just selecting materials; you’re investing in an entire philosophy of precision manufacturing.

The End about Mayvoci

1)Design:Over 100 paddle designs and photography service to assist start-up.

2)Professional:Focus on various of paddles manufacturing for 6 years

3)Quality:Strict quality management system to provide safety and satisfaction for customers

4)Amazon:Flexible comprehensive solution to make sure each Amazon seller is well cared.

5)Excellent Team:Experienced paddle experts & dynamic sales team give you 5-star service