Importance of Sample Production

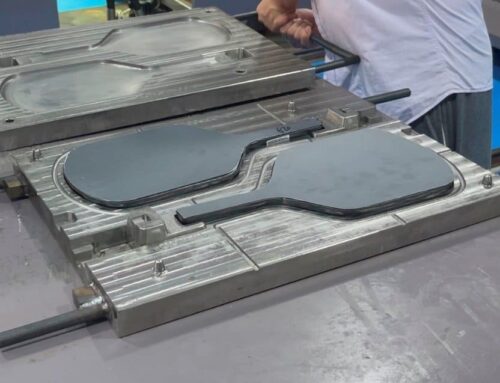

Sample production is a critical step in the development of Pickleball Paddles, allowing companies to verify the feasibility of product design and offer customers a chance to inspect the actual product. The primary role of sample production is to ensure that both the company and the customer understand the product’s quality, appearance, and functionality before mass production. This becomes especially significant when using advanced materials such as carbon fiber or fiberglass, as samples help evaluate the real-world performance of these materials.

As technology in Pickleball Paddle manufacturing has advanced, materials have evolved from traditional wood to high-performance composites. This transition underscores the growing importance of sample production. For example, carbon fiber not only reduces the weight of paddles but also increases rebound strength and durability. By testing the sample, companies can identify any technical issues that may affect the final product’s performance, ensuring that the paddle is competitive in the market.

The Role of Sample Production: Ensuring the Paddle Meets Market Demands

Sample production is a powerful tool for confirming that a product’s design meets the needs of the market. Through this process, companies can verify key parameters such as weight, feel, rebound strength, and spin effect. Customers can then provide feedback based on the sample’s actual performance, allowing for design optimization.

Moreover, sample production can help companies identify potential issues early on, preventing defects from being mass-produced. By rigorously testing the sample, businesses can adjust manufacturing techniques and material selections to ensure the mass-produced paddles meet the original design standards.

Defining Requirements and Goals for Pickleball Paddle Sample Production

Clearly defining the requirements and goals is crucial during sample production. Pickleball Paddles come in a variety of specifications, and customer needs can vary widely. As such, companies must carefully plan the production process according to customer preferences for materials, design, functionality, and aesthetics. For instance, professional players may prefer lighter paddles to enhance agility, while casual players might prioritize durability.

Additionally, businesses must consider how paddles perform in different playing environments. Outdoor paddles may need greater wear resistance and UV protection, whereas indoor paddles might require surface treatments to minimize glare. By defining these specifications, companies can produce paddles that meet both market and customer expectations.

Custom Sample Production: Key to Meeting Personalized Customer Needs

Customization is a growing trend in the Pickleball Paddle market, where many brands offer personalized paddles to boost customer engagement and meet specific needs. Sample production allows customers to experience these custom designs firsthand, ensuring the final product aligns with their preferences. Customers can choose different textures, color combinations, and even brand logos.

Custom sample production typically involves more complex processes than standard products, as it requires more communication and adjustments. This demands that suppliers maintain high flexibility in design and production to quickly meet customer needs and deliver high-quality custom paddles.

How to Effectively Communicate Paddle Specifications and Details with Suppliers

Effective communication with suppliers is key to successful sample production. Companies should provide detailed specifications, including materials, weight, dimensions, and surface treatments. For high-end custom orders, companies can use CAD drawings or 3D models to offer a clear presentation of the design, ensuring suppliers fully understand the customer’s expectations.

Additionally, maintaining close collaboration with suppliers during production ensures real-time feedback and adjustments. For instance, certain paddle surfaces may require specialized treatment to improve spin. With proper communication, these design aspects can be implemented successfully in the final product.

Time Management in Paddle Sample Production: How to Shorten Lead Times

Time management plays a crucial role in Pickleball Paddle production. To reduce lead times, companies can optimize their production workflows and implement advanced machinery. For instance, cold press molding can quickly shape materials without the need for heat, significantly cutting down production time.

In addition to workflow optimization, reducing unnecessary design revisions during sample production can also save time. Ensuring that the design is accurate early on minimizes the need for further adjustments, thereby shortening the entire production timeline.

Ensuring Consistency Between Samples and Mass-Produced Products

One of the main objectives of sample production is to ensure consistency between samples and mass-produced items. Companies should maintain identical materials, equipment, and manufacturing techniques for both the sample and the final product. For instance, using the same hot press technology will guarantee consistency in weight and rebound strength across the production line.

Furthermore, businesses should implement strict quality control processes during mass production, including regular sample testing. By doing so, companies can identify and address any discrepancies between the sample and mass-produced paddles early on, avoiding costly errors and ensuring consistent quality.

Differences Between Certified Samples and Regular Samples

Certified samples differ from regular samples in that they must undergo more rigorous testing and certification processes. For example, paddles intended for official competitions must be certified by the USAPA (USA Pickleball Association) to meet specific standards. Certification involves testing various aspects such as weight, friction, and surface treatment to ensure the paddle performs as required in competitive play.

While regular samples may suffice for recreational use, certified samples are crucial for brands aiming to penetrate high-end competitive markets. Although these samples may be more expensive to produce, they offer greater market credibility.

Why Sample Production Is More Expensive Than Mass Production

Sample production costs are typically higher than mass production due to the custom processes and material procurement involved. Since fewer units are produced, suppliers cannot benefit from economies of scale to reduce costs. Additionally, samples require multiple stages of testing and refinement, further driving up the costs.

Despite the higher expenses, sample production provides companies with the opportunity to verify designs and optimize manufacturing workflows, preventing quality issues from arising in large-scale production.

The End about Mayvoci

1)Design:Over 100 paddle designs and photography service to assist start-up.

2)Professional:Focus on various of paddles manufacturing for 6 years

3)Quality:Strict quality management system to provide safety and satisfaction for customers

4)Amazon:Flexible comprehensive solution to make sure each Amazon seller is well cared.

5)Excellent Team:Experienced paddle experts & dynamic sales team give you 5-star service