As a product manager for a seasoned pickleball paddle supplier, one of my key responsibilities is to assess potential manufacturing partners to ensure they meet the high standards we’ve set for our products. Recently, I visited a competitor’s factory to conduct an in-depth evaluation of their operations. This is a crucial task for anyone in the supply chain, especially for first-time visitors assessing a factory’s reliability. Here’s a breakdown of what I focused on during the tour and what I learned from the experience.

1. Production Environment: Cleanliness Reflects Efficiency

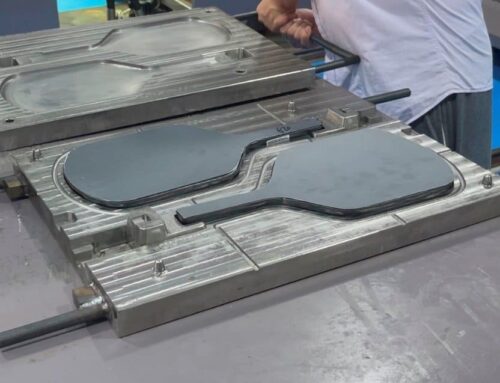

The moment I stepped into the factory, the first thing that caught my eye was how clean and organized the production floor was. As someone familiar with the nuances of manufacturing, I know that a tidy workspace often signals an efficient operation. The factory was divided into clear sections for each stage of the pickleball paddle production: cutting carbon fiber, assembling the honeycomb core, and applying surface treatments like peel-ply.

A clutter-free and well-organized space isn’t just for show; it reduces the risk of errors and ensures that each stage of the process flows smoothly. The factory manager explained their routine of cleaning after every shift to maintain a safe and efficient workspace. This kind of discipline reassured me that the factory was equipped to handle large-scale production while maintaining high standards of quality.

Takeaway: Cleanliness and organization are signs of a well-run factory. For first-time visitors, observing the factory floor’s condition can provide valuable insights into the factory’s efficiency and operational discipline.

2. Quality Control: Ensuring Every Detail is Checked

As we moved through the factory, I paid special attention to their quality control processes. In our line of work, quality is everything. A single defective paddle can not only affect the customer experience but also damage a brand’s reputation. This factory had inspection stations set up at every stage of production. I watched as quality control inspectors checked the thickness of the carbon fiber sheets, measured the core structure’s precision, and tested the surface grip of the paddles to ensure the right level of friction.

The factory manager also showed me their lab, where they test paddles for durability and performance. The test results for various batches of paddles were impressive, with consistent performance ratings. Knowing that the factory takes quality control seriously from the raw materials to the final product gave me confidence in their ability to maintain high standards.

Takeaway: A factory’s quality control process should be robust and visible at every step. Make sure to ask for test results and see if their lab can provide data to back up their claims.

3. Production Capacity: Can They Meet Our Demands?

Once I was satisfied with their quality control, my next concern was production capacity. We frequently receive large orders with tight deadlines, and I needed to ensure this factory could handle such demands. The manager walked me through their production lines, explaining that they were currently producing 16mm thick honeycomb-core paddles. The line was efficient, and the manager assured me that their daily output was sufficient to meet the demand of large orders.

I also inquired about their lead times and how they handle spikes in demand. They had a detailed plan for scaling production during peak seasons, which included stocking up on raw materials in advance to avoid delays. This flexibility is crucial for us, especially during busy periods when customer demand can skyrocket.

Takeaway: Always assess whether the factory’s production capacity can match your order requirements. Ask about their lead times and how they manage production during peak times to ensure they can deliver on time.

4. Employee Management and Training: Stability Matters

Beyond machinery and processes, I was curious about the workforce. A factory’s ability to produce consistent, high-quality products depends heavily on the skills and experience of its workers. I asked about their employee turnover rates and training programs. To my surprise, many of their workers had been with the company for several years, which is a rare but valuable asset in manufacturing.

The factory manager explained that all new hires go through an extensive training program before handling critical production tasks. This level of attention to workforce development showed me that the factory invests in its people, which directly contributes to the quality of the products they produce.

Takeaway: A stable, well-trained workforce is crucial for maintaining consistent production quality. Don’t hesitate to ask about employee retention rates and the type of training workers undergo before handling production tasks.

5. Documentation and Certifications: Legitimacy and Compliance

Finally, I made sure to verify the factory’s certifications and legal documents. The manager provided me with their ISO quality management certification and their export licenses. This step is vital, as working with a factory that lacks the proper certifications could lead to serious issues down the line, including delays in customs or regulatory non-compliance.

They also showed me records of their previous large-scale orders, which gave me confidence in their ability to handle international shipments and deliver products that meet global standards.

Takeaway: Always ask to see a factory’s certifications and export documentation. This will ensure that they comply with international standards and can meet your specific market requirements.

Conclusion

As a supplier, choosing the right manufacturing partner is a critical decision that can make or break your business. During my factory visit, I was able to evaluate the cleanliness, quality control, production capacity, workforce stability, and compliance of this potential partner. For those visiting a factory for the first time, focusing on these key areas will help you make informed decisions and ensure that you choose a reliable, efficient, and compliant partner for your business.

By focusing on these aspects, you’ll be well-equipped to assess any factory and make a confident choice about whether they are the right fit for your needs.

The End about Mayvoci

1)Design:Over 100 paddle designs and photography service to assist start-up.

2)Professional:Focus on various of paddles manufacturing for 6 years

3)Quality:Strict quality management system to provide safety and satisfaction for customers

4)Amazon:Flexible comprehensive solution to make sure each Amazon seller is well cared.

5)Excellent Team:Experienced paddle experts & dynamic sales team give you 5-star service