Before discussing the grip issues of cold-pressed paddles, it’s essential to understand how these paddles are made. In the production process, the sides of the handle are left untreated before wrapping the grip, leading to discomfort during use and quicker wear of the grip. After a month of research, we identified 893 complaints regarding these issues. The complaints clearly show customer dissatisfaction and a desire for change. However, the reality is that the profit margins for cold-pressed paddles are low, and most suppliers focus on thermoformed paddles, testing new materials, and improving manufacturing processes. Despite this, cold-pressed paddles are commonly used by beginners. A comfortable cold-pressed paddle can significantly enhance the user experience. Therefore, our company has dedicated part of our R&D team and resources to address this issue. We are now ready to showcase our progress:

Improvement Methods

1. Carbon Fiber Wrapping: Inspired by thermoforming processes, we wrap the sides of the handle with carbon fiber sheets, preventing the honeycomb core from being exposed and improving the grip feel.

2. PU Material Filling: We fill the area around the handle with PU material, which provides a better feel compared to EVA patches, enhancing overall comfort.

Detailed Expansion

Cold-Pressed Paddle Production Process

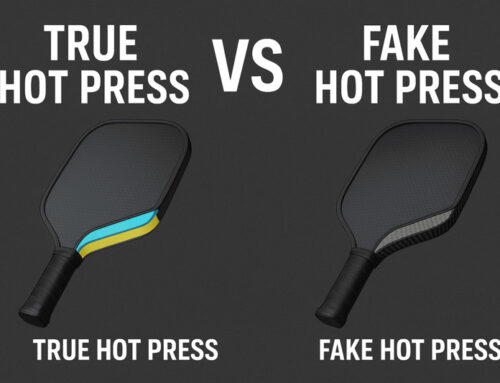

The production process of cold-pressed paddles is relatively simple. It involves bonding pre-shaped paddle faces with a honeycomb core and adding an edge guard. Before wrapping the grip, the sides of the handle are left untreated, leading to grip issues. In contrast, the thermoforming process is more complex but offers better overall grip and durability.

User Feedback

Analysis of the 893 complaints revealed key areas of user dissatisfaction:

1. Grip Comfort: Many users report discomfort in the handle area during prolonged use, affecting their performance.

2. Durability: The untreated sides of the handle are more prone to wear, especially under high-intensity use.

3. Overall Experience: Many beginners find that poor grip comfort significantly impacts their initial experience with the sport.

Market Status

Due to the low profit margins of cold-pressed paddles, many suppliers prefer investing in new materials and processes for thermoformed paddles. However, ignoring the cold-pressed paddle market could mean missing out on a large segment of beginner players. Recognizing this market potential, our company has invested resources in improvement efforts.

Phase Results

1. Carbon Fiber Wrapping: This method not only protects the honeycomb core but also provides additional structural strength and durability to the handle.

2. PU Material Filling: Compared to traditional EVA patches, PU material is softer and more durable, significantly enhancing the comfort of the grip.

Conclusion

By improving the handle design of cold-pressed paddles, we aim to provide beginners with a better user experience. This will not only increase their interest in the sport but also improve their performance. We will continue to invest in research and development to introduce more improved products in the near future.

We believe these improvements will receive positive feedback from the market and bring new vitality to the cold-pressed paddle market. Stay tuned for our latest products and experience more comfortable and durable cold-pressed paddles.

The End about Mayvoci

1)Design:Over 100 paddle designs and photography service to assist start-up.

2)Professional:Focus on various of paddles manufacturing for 6 years

3)Quality:Strict quality management system to provide safety and satisfaction for customers

4)Amazon:Flexible comprehensive solution to make sure each Amazon seller is well cared.

5)Excellent Team:Experienced paddle experts & dynamic sales team give you 5-star service