In the era of globalization, China, as the world’s factory, attracts countless international buyers due to its manufacturing capabilities and comprehensive industrial chains. However, sourcing from China is not just about placing orders and receiving goods; effective time management is a crucial factor that determines the success of the entire supply chain. Time not only affects costs but also impacts the efficiency and stability of the entire procurement process. For buyers, mastering the optimal time to procure and avoiding potential delays has become a critical aspect of the sourcing process.

Time Management: The Key to Successful Sourcing from China

Effective time management is the cornerstone of successful sourcing from China. From placing orders, production, to final delivery, every step can be influenced by time-related factors. Buyers must not only fully understand the supplier’s production capacity but also make accurate predictions regarding China’s logistics system, customs clearance processes, and holiday schedules. Any delay in one of these areas can disrupt the entire supply chain. By implementing scientific time planning, companies can avoid unnecessary waiting times and delays, ensuring the smooth operation of sourcing from China.

How to Identify Key Time Nodes in Procurement

Identifying and seizing key time nodes in procurement can help buyers effectively prevent potential delays. Time nodes in procurement can be divided into three critical stages: ordering time, production time, and transportation time. Ordering time directly affects the supplier’s production schedule, especially during peak periods. Placing orders early ensures priority in production. Production time is another critical node, and understanding production cycles and the supplier’s capacity helps avoid delays. Transportation time depends on the progress of logistics companies and customs clearance, ensuring timely delivery of goods. Identifying and arranging these key nodes efficiently will greatly improve procurement accuracy.

The Impact of Major Chinese Holidays on Procurement

China’s holidays have profound impacts on supply chains, especially for international buyers. These holidays often go overlooked, becoming a major factor in procurement delays. Chinese holidays are not just about halting work; they also lead to production shutdowns and slow logistics operations. Common holidays include Chinese New Year, Labor Day, and National Day. The length and impact of these holidays are significant, and if buyers are not prepared in advance, they may face supply chain disruptions. When creating procurement plans, it’s crucial to factor in these holidays and avoid delays caused by holidays.

Supply Chain Disruptions During Chinese New Year

Chinese New Year is the most important traditional holiday in China. Most factories close two weeks before the holiday, and workers return home, with normal production resuming only after the holiday. This means that the supply chain is essentially at a standstill for over a month. For international buyers, procurement plans during the Chinese New Year must be handled with extreme caution. To avoid supply chain disruptions, buyers should communicate with suppliers well in advance to ensure that orders are completed before the holiday. Additionally, preparations should be made for post-holiday production to avoid further delays.

The Potential Delay Risks of Labor Day and National Day

Apart from Chinese New Year, Labor Day and National Day are also holidays that significantly affect procurement. These holidays usually last for a week, during which most factories shut down, and logistics services are greatly reduced. National Day, in particular, is known as the “Golden Week” in China, where nationwide travel peaks, putting enormous pressure on the logistics industry, leading to decreased transportation efficiency and extended delivery cycles. Buyers planning to place orders during Labor Day or National Day should pay special attention to the holiday schedule to avoid delays that could disrupt the entire procurement chain.

The Massive Impact of the Double Eleven Shopping Festival on Logistics

In recent years, the Double Eleven shopping festival has become the world’s largest shopping event. During this period, a surge in orders puts enormous pressure on the logistics industry, causing an overload in the transportation network. For international buyers, the risk of logistics congestion during Double Eleven is particularly high. Both shipping costs and delivery times increase significantly during this period. To avoid the logistical bottleneck, buyers should try to avoid placing orders before and after Double Eleven and arrange shipment in advance to ensure timely delivery.

The Impact of Climate Factors on Procurement: Typhoon and Rainy Seasons

Climate change is another critical factor affecting procurement timelines. Southern and coastal regions of China experience typhoon seasons annually, and frequent adverse weather conditions affect both factory production and transportation. For international buyers who rely on maritime transport, the typhoon season may lead to port closures and delays in loading. Additionally, the rainy season can cause logistics delays, especially in road transport, where flooding and roadblocks are common. Buyers should plan production and transportation schedules based on the climate characteristics of the procurement destination to avoid time losses caused by natural disasters.

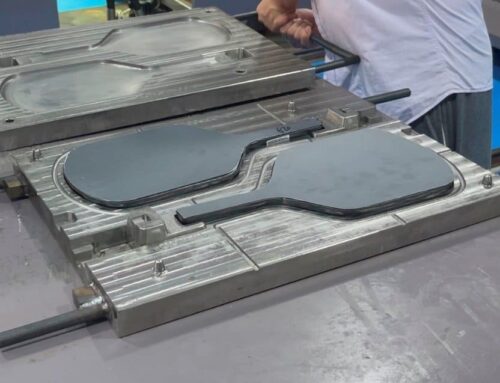

Procurement Planning for Peak and Off-Season in the Pickleball Industry

In the pickleball industry, there are clear fluctuations in demand during different periods. The peak season typically occurs around spring and summer, and before major tournaments, while the off-season occurs during autumn and winter. These seasonal fluctuations present challenges to supply chain stability. During peak seasons, the production cycle is often extended, and suppliers may face order backlogs. During the off-season, buyers have more time to negotiate better prices with suppliers. Buyers must plan procurement in advance based on market demand to avoid being passive during peak seasons, which can lead to delays or increased costs.

The Importance of Early Planning and Booking

The essence of procurement lies in planning, and early planning is the best strategy to avoid delays. Buyers need to forecast future orders based on market demand and communicate with suppliers months in advance to arrange production. This ensures that goods can be delivered on time and avoids delays caused by suppliers’ insufficient production capacity. Additionally, booking logistics in advance is equally crucial, especially during holidays or industry peak seasons when logistics resources are often tight. Early booking ensures timely shipment and avoids delivery delays caused by tight scheduling at logistics companies.

How to Establish Long-Term Cooperation to Reduce Time Risks

Long-term cooperation can greatly reduce time risks and ensure smooth procurement processes. Building long-term, stable relationships with suppliers not only ensures priority in order processing but also reduces communication costs and improves efficiency. Suppliers often prioritize long-term customers, especially when production capacity is tight, by giving them production and shipping priority. Additionally, long-term cooperation helps buyers gain a deeper understanding of the supplier’s production cycles and processes, allowing for more accurate procurement planning and avoiding unnecessary delays.

How to Effectively Utilize Third-Party Sourcing Agents

For many international buyers, third-party sourcing agents are an effective tool for reducing the pressure of time management. Professional sourcing agents not only help buyers find suitable suppliers but also coordinate all aspects of the supply chain, including production, transportation, and customs clearance. Especially when handling large orders or multi-product sourcing, third-party agents can integrate resources to ensure orders are completed on time. Furthermore, sourcing agents can help buyers handle language barriers, time zone differences, and other complexities, further improving procurement efficiency and accuracy.

Optimizing Procurement Time Using Big Data and Smart Technology

In modern supply chain management, the application of smart technology and big data is gradually transforming how procurement timelines are managed. Through big data analysis, buyers can accurately predict market demand changes and arrange procurement schedules scientifically to avoid delays caused by placing orders during peak periods. Meanwhile, smart supply chain management systems can monitor the production and transportation progress in real time, identifying potential risks and ensuring that orders are completed smoothly. By leveraging these technological tools, buyers can optimize time management and enhance the flexibility and responsiveness of the entire supply chain.

Coordinating Local and International Logistics Timelines

For international procurement, coordinating international logistics with local logistics is crucial. International transport often involves multiple steps and uncertainties, such as customs clearance delays or shipping delays, while local logistics are key to ensuring timely delivery. Buyers must communicate with logistics companies in advance to ensure seamless coordination between international and local shipping to avoid any delays at the final delivery stage. Through proper time coordination, buyers can ensure that goods arrive at their destination on time, reducing uncertainties in the procurement timeline.

Conclusion: Effective Time Planning to Avoid Unnecessary Delays

Mastering procurement time planning is the key to successful sourcing from China. By identifying time nodes in advance, avoiding holiday schedules, preparing for climate impacts, and establishing long-term cooperation with suppliers, buyers can effectively reduce the risk of delays. Meanwhile, leveraging big data and smart technology to optimize time management helps improve supply chain efficiency and stability. In the future globalized market, effective procurement time planning will not only lower costs but also provide companies with greater competitive advantages.

The End about Mayvoci

1)Design:Over 100 paddle designs and photography service to assist start-up.

2)Professional:Focus on various of paddles manufacturing for 6 years

3)Quality:Strict quality management system to provide safety and satisfaction for customers

4)Amazon:Flexible comprehensive solution to make sure each Amazon seller is well cared.

5)Excellent Team:Experienced paddle experts & dynamic sales team give you 5-star service