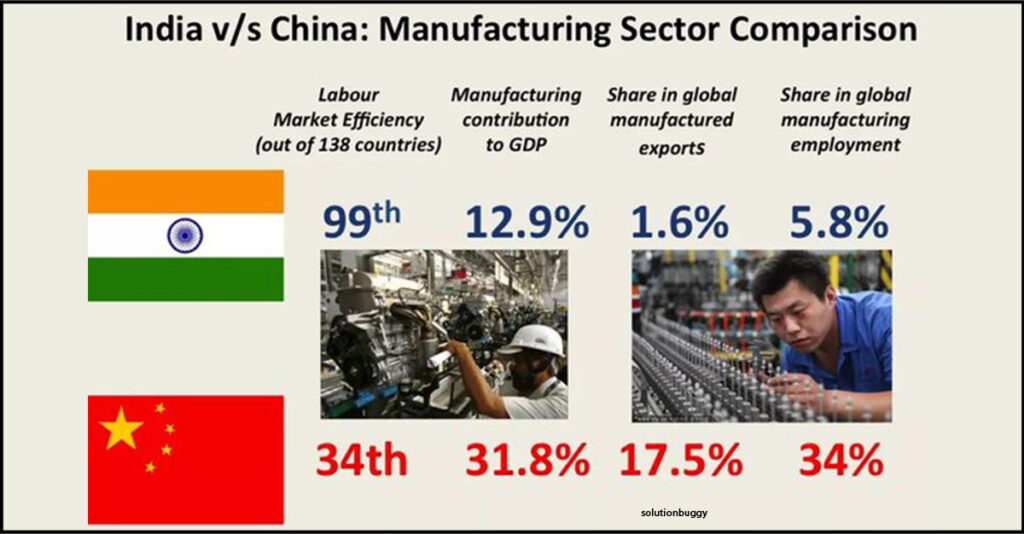

The global pickleball boom has created a massive demand for paddles, and two Asian giants are central to meeting it: China and India. While often grouped as low-cost alternatives to Western manufacturing, their profiles are remarkably distinct.

Understanding the nuanced strengths and weaknesses of each is crucial for any brand looking to optimize its supply chain for performance, cost, and risk.

1. Cost Structure: Calculated Efficiency vs. Raw Cost Advantage

The initial cost picture seems straightforward, but the real calculation is more complex.

- China: The Efficiency Play

While its absolute labor cost advantage has narrowed, China’s strength lies in superior overall efficiency. Advanced automation and deeply integrated supply clusters in regions like Guangdong allow Chinese factories to achieve a lower cost-per-unit through high-speed, large-volume production. The infrastructure—from ports to roads—ensures reliability, minimizing hidden delays and costs. - India: The Labor Cost Play

India retains a significant advantage in pure labor hourly rates. This makes it competitive for more labor-intensive assembly processes. However, this can be offset by less robust infrastructure and complex local regulations, which can introduce inefficiencies and hidden logistical costs. Government initiatives like “Production Linked Incentive (PLI)” schemes are aimed at improving this calculus.

The Bottom Line: China often wins on total landed cost and speed for large orders. India presents an opportunity for lower direct labor costs, suitable for less time-sensitive production.

2. Technical Capabilities: Advanced Materials vs. Craftsmanship & Adaptation

The technological focus of each country reflects its industrial maturity.

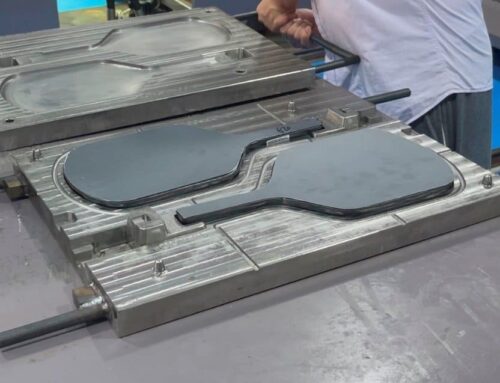

China: Focus on Materials and Precision

Chinese manufacturers are leaders in integrating advanced materials like T700-grade carbon fiber and perfecting complex processes like thermal compression molding. Their R&D is heavily geared towards process innovation and achieving performance benchmarks that meet global standards, supported by significant investment in proprietary technology.India: Leveraging Tradition and Policy Support

India’s technical strength has historically been in skilled craftsmanship, evident in its large leather goods and sports equipment clusters. The focus is now on technological upgrading, heavily supported by government-driven initiatives. Programs like the “ZED (Zero Defect Zero Effect)” certification scheme are designed to push SMEs towards higher quality standards and modern manufacturing practices.

The Bottom Line: For high-performance paddles requiring cutting-edge materials, China is the proven choice. India is a growing hub for skill-based manufacturing that is rapidly modernizing with policy backing.

3. Quality Control: Systematic Consistency vs. Evolving Standards

Quality reliability is a primary concern for brands protecting their reputation.

China: Predictable, Systematized Quality

Established Chinese factories operate with robust, process-driven Quality Management Systems. They are adept at adhering to strict international standards, including USAPA certification. High levels of automation in inspection ensure consistent output and high product uniformity across massive production runs.India: A Focus on Quality Upliftment

Quality can be more variable, but the trajectory is positive. The government’s ZED scheme is a major force, incentivizing manufacturers to adopt formal quality management processes. The most reliable Indian suppliers are often those who have already secured long-term partnerships with European or American brands, as this exposure enforces higher standards.

The Bottom Line: China offers lower risk and proven consistency for quality at scale. Partnering with India requires more diligent supplier vetting and quality audits, but can yield reliable partners who are committed to improvement.

4. Scalability & Supply Chain: Unmatched Speed vs. Developing Agility

The ability to ramp up production and deliver reliably is a key differentiator.

China: The Scalability Titan

The Chinese supply chain ecosystem is built for speed and volume. A full paddle can be sourced from components within a tight geographic radius, enabling rapid turnaround times. It is not uncommon for major factories to boast production capacities in the tens of millions of paddles annually.India: Building Capacity Amidst Challenges

Scalability is hampered by infrastructure bottlenecks, as some manufacturers note the lack of port and road facilities comparable to China’s. However, the development of Industrial Clusters and Common Facility Centers is a strategic move to consolidate capacity and improve supply chain fluidity for specific sectors.

The Bottom Line: For getting large volumes to market quickly and reliably, China is unmatched. India is better suited for medium-volume orders or as a strategic diversification play to mitigate supply chain risk.

Strategic Supplier Selection Guide

Your choice should align with your brand’s primary objectives:

Choose China if your priorities are:

Top-Tier Performance: You need paddles made with the latest advanced materials.

Massive, Rapid Scalability: You must stock shelves for a booming market without delay.

Predictable Quality: You require consistent, high-quality output with minimal oversight.

Choose India if your priorities are:

Optimizing for Labor Cost: Your product is less automation-dependent.

Supply Chain Diversification: You are building a “China-Plus” strategy to mitigate risk.

Leveraging Incentives: You can benefit from government manufacturing subsidies.

Before committing, always audit the factory, request samples for independent testing, and verify their certifications and major client portfolios. The right partner exists in both countries; the key is aligning their inherent strengths with your strategic needs.

The End about Mayvoci

1)Design:Over 100 paddle designs and photography service to assist start-up.

2)Professional:Focus on various of paddles manufacturing for 6 years

3)Quality:Strict quality management system to provide safety and satisfaction for customers

4)Amazon:Flexible comprehensive solution to make sure each Amazon seller is well cared.

5)Excellent Team:Experienced paddle experts & dynamic sales team give you 5-star service