1. Choose the Right Inventory Management Software

- Assess Needs:

Determine the essential features your business requires, such as realtime inventory tracking, automatic reorder alerts, and data analysis.

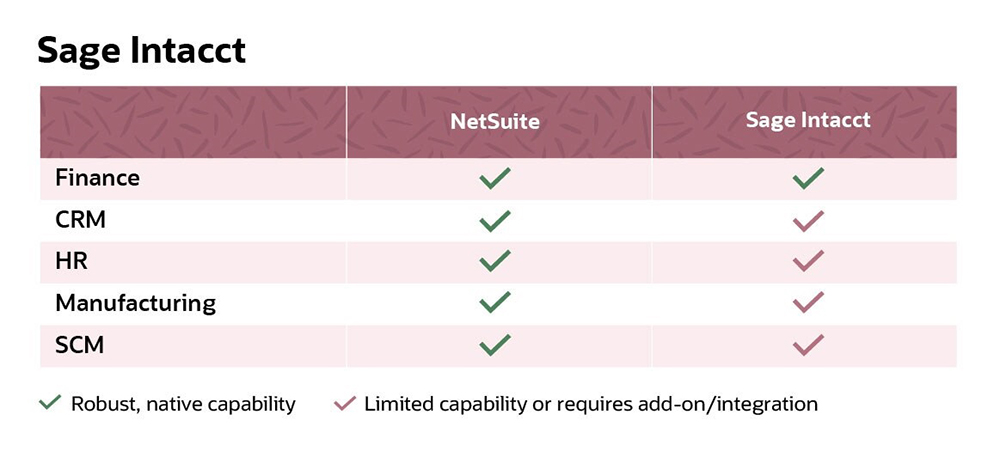

- Research and Select Software:

Compare inventory management software available in the market, such as NetSuite, Lightspeed, and QuickBooks, and choose the one that best fits your business needs.

- Implementation and Training:

Purchase and install the software, and train your staff to ensure they are familiar with all functionalities and processes.

Action Plan:

Conduct a needs assessment and list the required features.

Investigate various software options and read user reviews.

Schedule software demos and discuss specific requirements with vendors.

Purchase the software and arrange for implementation and staff training.

2. Implement Safety Stock Management

- Data Collection:

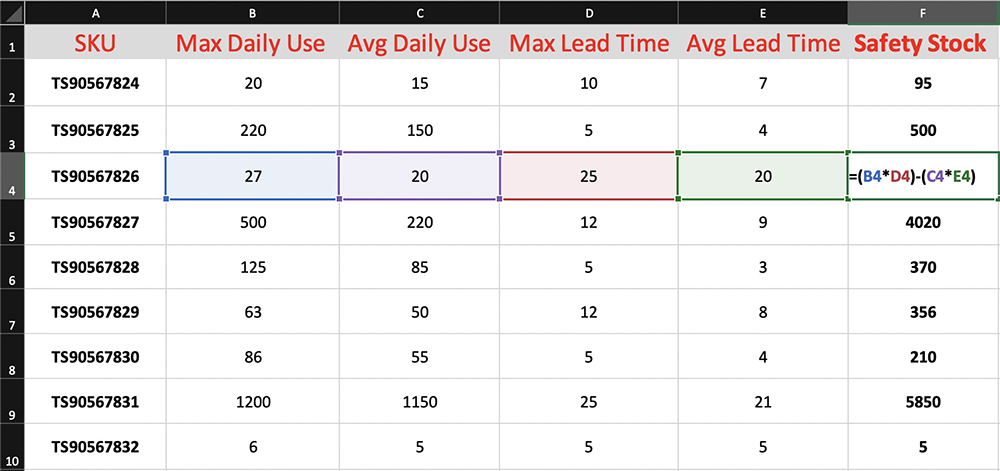

Gather sales data from the past year, including sales volume, sales cycles, and seasonal demand for each Pickleball Paddle model.

- Set Safety Stock Levels:

Use the sales data and future demand forecasts to set appropriate safety stock levels for each product.

- Monitor and Adjust:

Regularly monitor inventory levels and adjust safety stock based on actual sales performance and market changes.

Action Plan:

Use historical sales data to calculate average demand and fluctuations for each product.

Set initial safety stock levels (e.g., based on one month’s demand).

Establish a regular review process (monthly or quarterly) to adjust safety stock as needed.

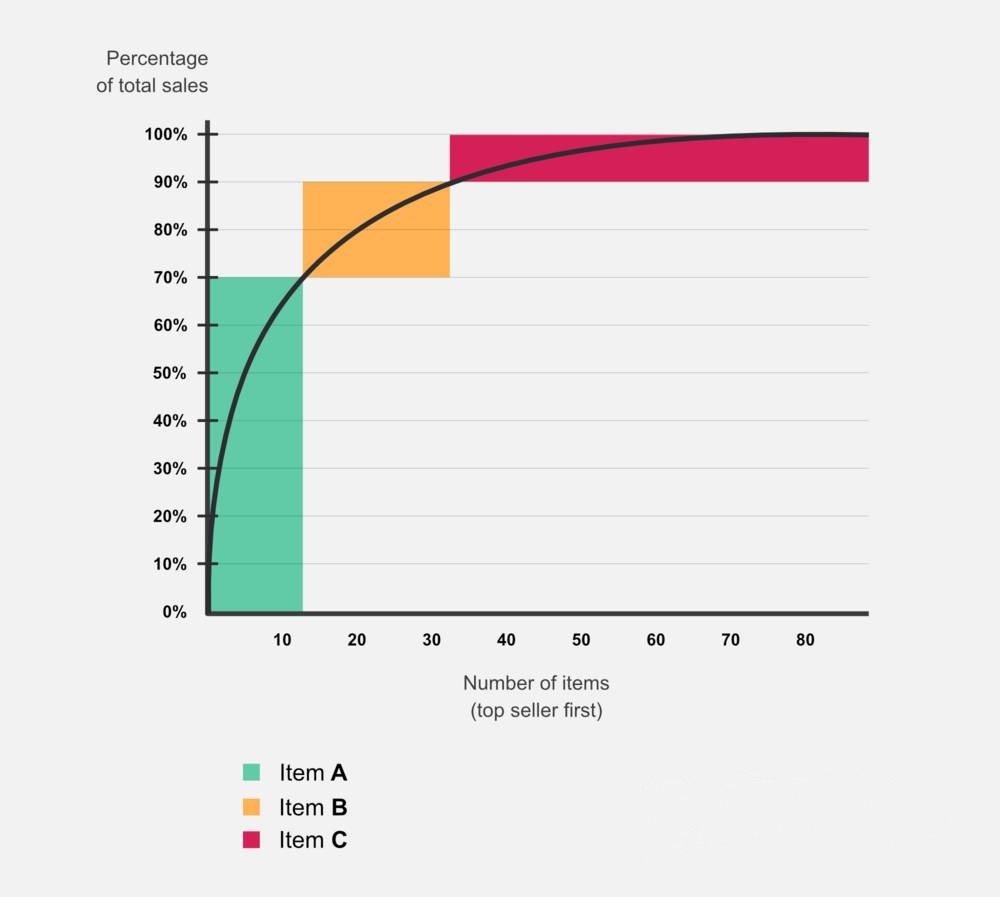

3. Implement the ABC Classification Method

- Data Analysis:

Analyze the past year’s sales data and classify products by value and sales frequency.

- Classify Inventory:

Divide products into three categories: A (high value, low quantity), B (moderate value, moderate quantity), and C (low value, high quantity).

- Focused Management:

Prioritize the management of Aclass products by regularly reviewing inventory levels and sales performance to optimize reorder strategies.

Action Plan:

Generate product sales reports using inventory management software.

Perform ABC classification to ensure accurate categorization.

Implement stricter management and monitoring processes for Aclass products.

4. Conduct Regular Inventory Counts

- Develop Inventory Count Schedule:

Create an annual schedule for inventory counts, specifying monthly or quarterly tasks.

- Execute Inventory Counts:

Assign staff to conduct inventory counts, record actual stock levels, and compare with system records.

- Reconcile Data and Adjust:

Identify discrepancies between actual inventory and system records, investigate causes, and update records accordingly.

Action Plan:

Establish a detailed inventory count timetable.

Train staff on inventory counting procedures and standards.

Use barcode scanning devices to enhance count accuracy and efficiency.

5. Set Reasonable Reorder Points

- Calculate Economic Order Quantity (EOQ):

Determine the optimal order quantity for each product based on demand, ordering costs, and holding costs.

- Set Reorder Points:

Establish reorder points for each product based on sales velocity and lead time, ensuring timely reordering.

- Automate Reordering:

Use the inventory management software’s automatic reorder functionality to generate purchase orders when inventory reaches the set reorder points.

Action Plan:

Calculate EOQ and reorder points for each product.

Input reorder points into the inventory management software.

Regularly review and adjust reorder points to match actual demand.

Conclusion

By selecting the right inventory management software, setting safety stock levels, implementing the ABC classification method, conducting regular inventory counts, and setting reasonable reorder points, businesses can achieve efficient inventory management, reduce costs, and improve operational efficiency. These methods are particularly crucial for companies manufacturing and selling Pickleball Paddles, ensuring market competitiveness and customer satisfaction.

The End about Mayvoci

1)Design:Over 100 paddle designs and photography service to assist start-up.

2)Professional:Focus on various of paddles manufacturing for 6 years

3)Quality:Strict quality management system to provide safety and satisfaction for customers

4)Amazon:Flexible comprehensive solution to make sure each Amazon seller is well cared.

5)Excellent Team:Experienced paddle experts & dynamic sales team give you 5-star service